Department of Chemical Engineering has state of art laboratories with modern equipment/instruments to train the students with latest technology.

µ

µ

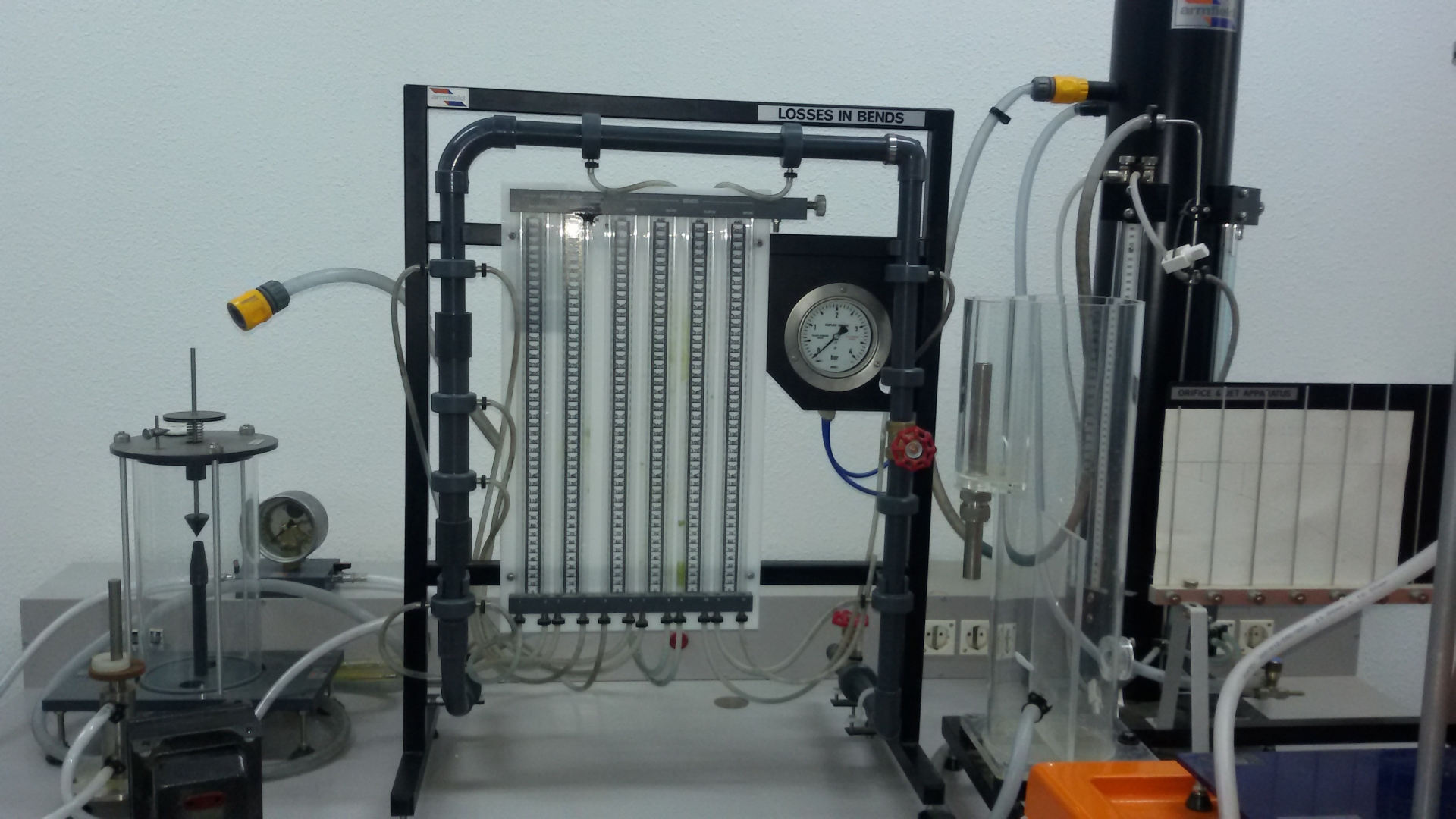

Momentum Transfer Lab:

- Reynolds demonstration

- Flow meter demonstration

- Bernoulli's theorem demonstration

- Flow through an orifice apparatus

- Energy losses in pipes

- Energy losses in bends

- Impact of Jet

| Fluid friction due to fittings; Flow measurement devices. Reynolds experiment | Hydrostatic bench with friction in pipe apparatus |

|

|

|

Fixed and Fluidized bed |

Fluid mixing apparatus |

|

|

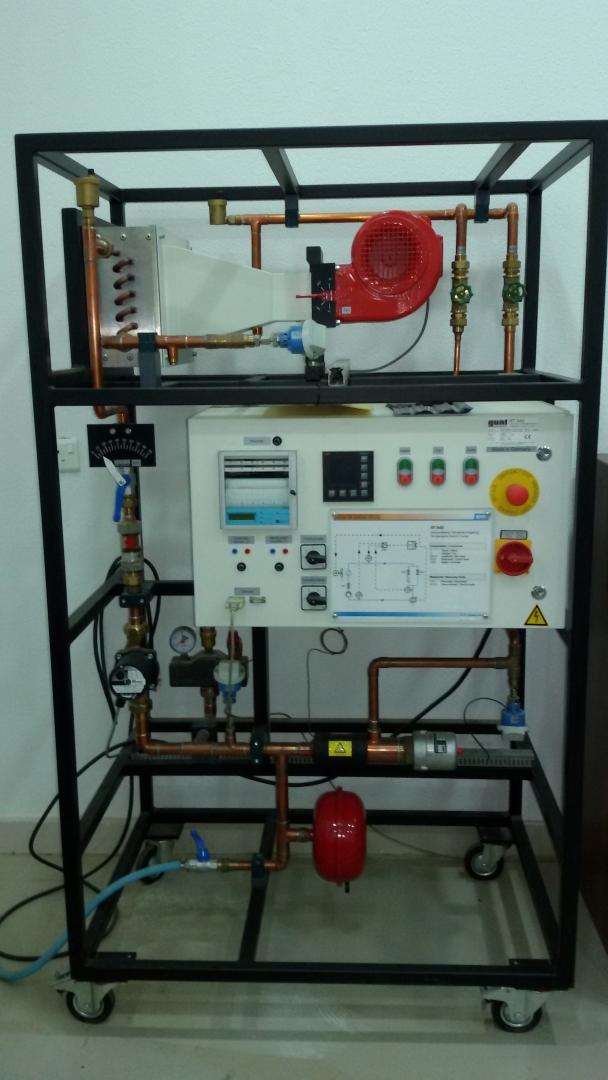

Heat Transfer Lab. :

- Radial Heat Conductivity

- Liner Heat Conductivity

- Thermal conductivity for Metals

- Combined free convection and Radiation

- Forced Convection

- Heat Radiation

- Tubular Heat Exchanger

- Shell and Tube Heat Exchanger

- Plate Heat Exchanger

- Jacketed Vessel

|

Heat Exchanger service unit

|

Cooling tower

|

|

Jacketed Vessel with Stirrer & Coil

|

Plate Heat Exchanger

|

|

Tubular Heat Exchanger

|

Sell & Tube Heat Exchanger

|

|

Steam generator

|

Catalysis and Catalytic Reaction Engineering:

- Diffusion of Liquids KCLL

- Refractive Index

- Variation of Boil up Rate

- Distillation - Overall Column Efficiency

- Distillation at Constant Reflux Ratio

- Wetted Wall Gas Absorption -Nitrogen free

- Wetted Wall Gas Absorption -with nitrogen

Absorption of CO2 in Water

- Nominal Velocity of Air in Water Cooling Tower

- Liquid Nitrogen Generator

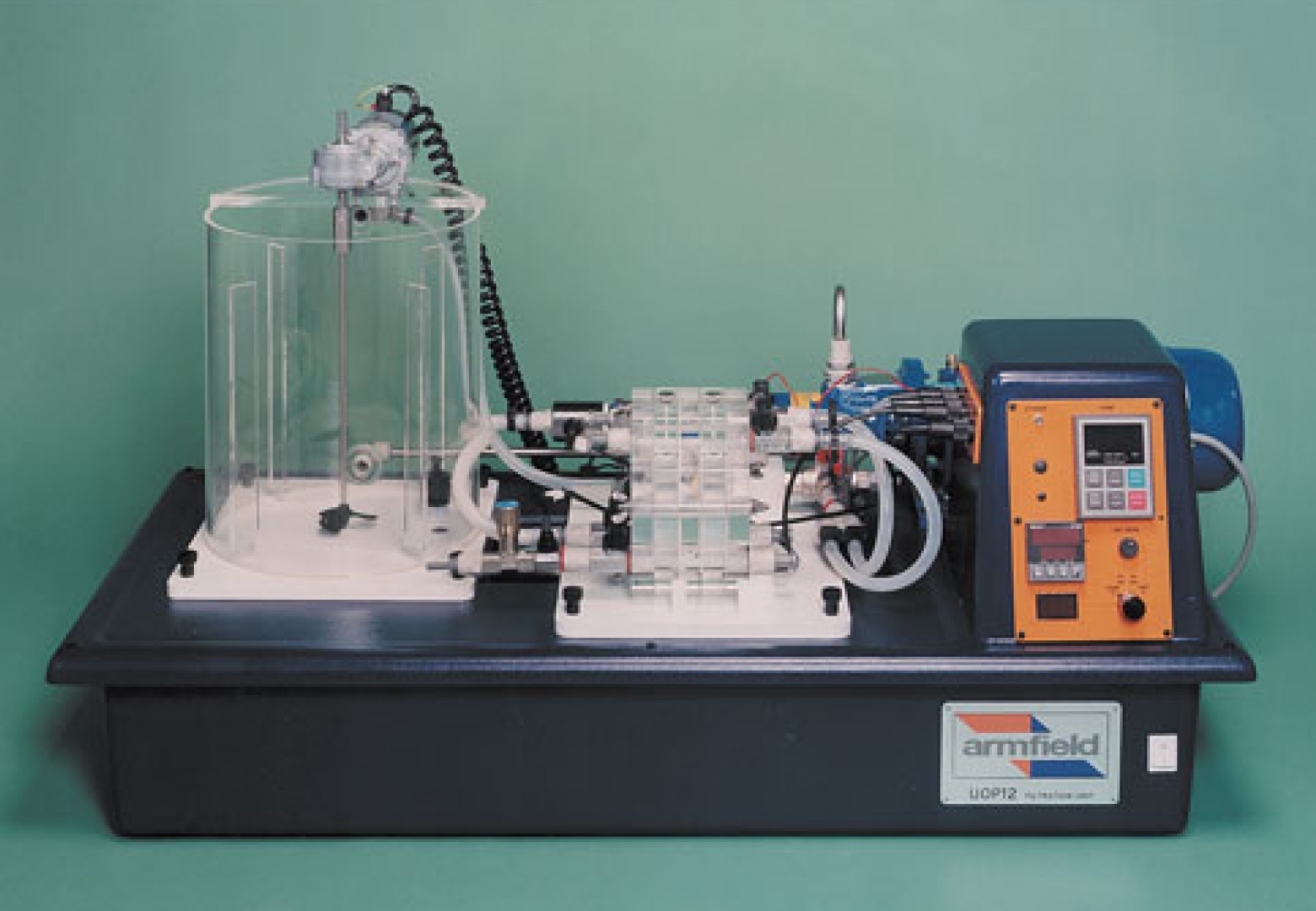

Chemical reactors set: Batch; CSTR and PF

|

|

Liquid Nitrogen Generator |

Catalytic reactors |

Mass transfer lab:

- Diffusion of Liquids KCLL

- Refractive Index

- Variation of Boil up Rate

- Distillation - Overall Column Efficiency

- Distillation at Constant Reflux Ratio

- Wetted Wall Gas Absorption -Nitrogen free

- Wetted Wall Gas Absorption -with nitrogen

- Absorption of CO2 in Water

- Nominal Velocity of Air in Water Cooling Tower

|

Batch Distillation Unit |

Absorption Column

|

|

Wetted Wall Absorption Column |

Absorption Column |

|

Crystallization Unit

|

Adsorption Unit

|

Separation Processes lab:

- Studying drying process for drying of wet sand.

- Determination of humidity using psychrometer chart.

- Studying the drying process under natural drying conditions.

- Determination of supersaturation and supersaturation ratio for a crystallization process.

- Determination of crystal size distribution.

- Study and calibration of feed pump for liquid-liquid extraction process.

- Studying the extraction of caffeine from coeffee beans.

- Extraction of KHCO3 from polymide pellet using solid-liquid extraction unit as batch process.

- Extraction of KHCO3 by configuring the unit as single stage process.

- Extraction of KHCO3 by configuring the unit as two stage process.

|

Liquid - Liquid Extraction Unit

|

Solid - Liquid Extraction Unit

|

|

Try Dryer

|

Filtration Unit

|

Water and Environment Laboratory.

- PH measurement of different water sample.

- Conductivity different water sample

- DO different water sample

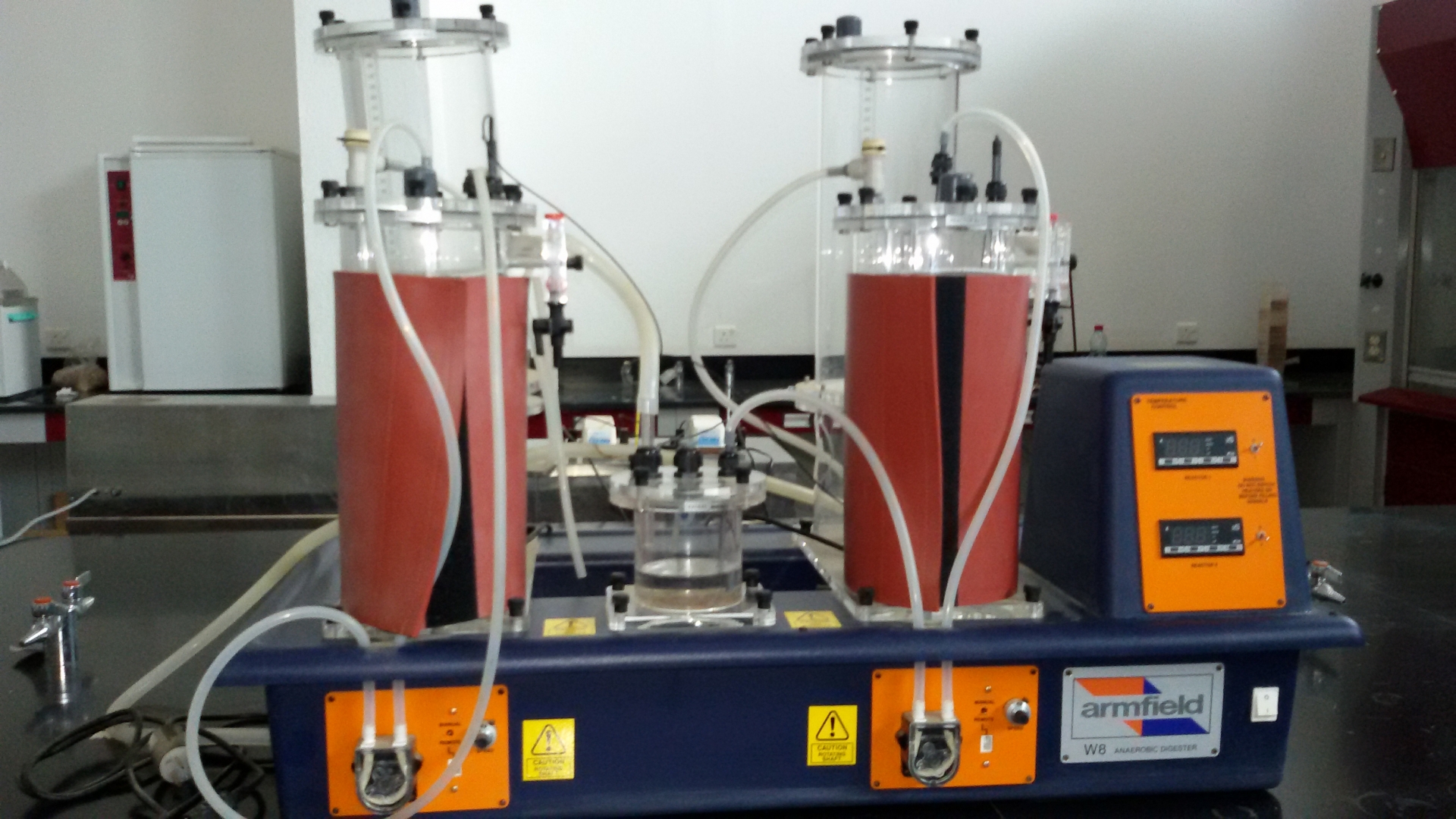

- Study of Aerobic digestion of waste water

- Anaerobic digestion of waste water

- TDS different water sample

- TSS different water sample

- Sedimentation different water sample

|

Aanaerobic Digestor

|

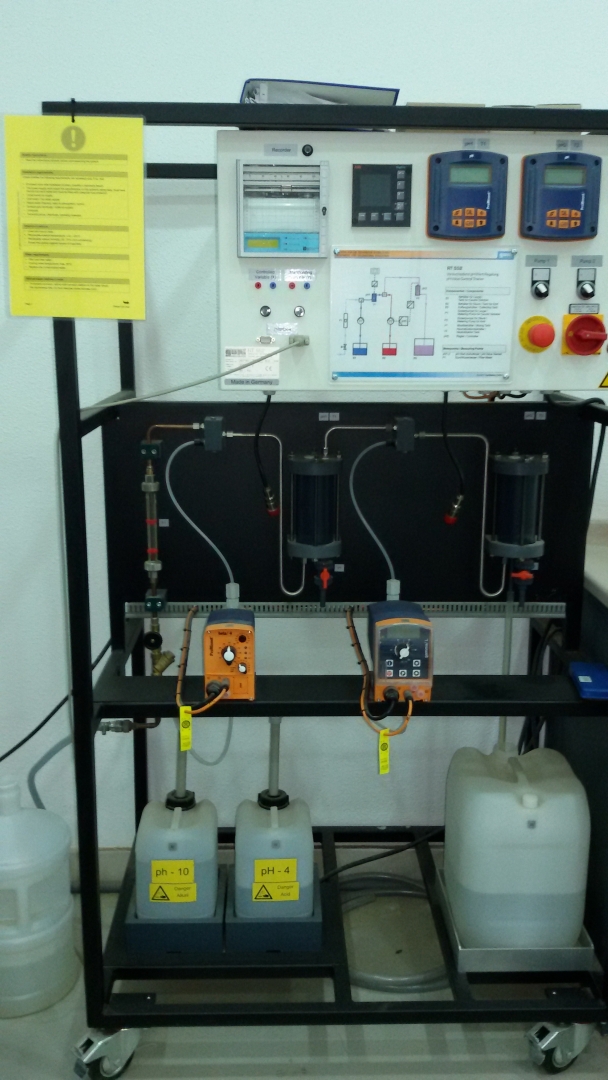

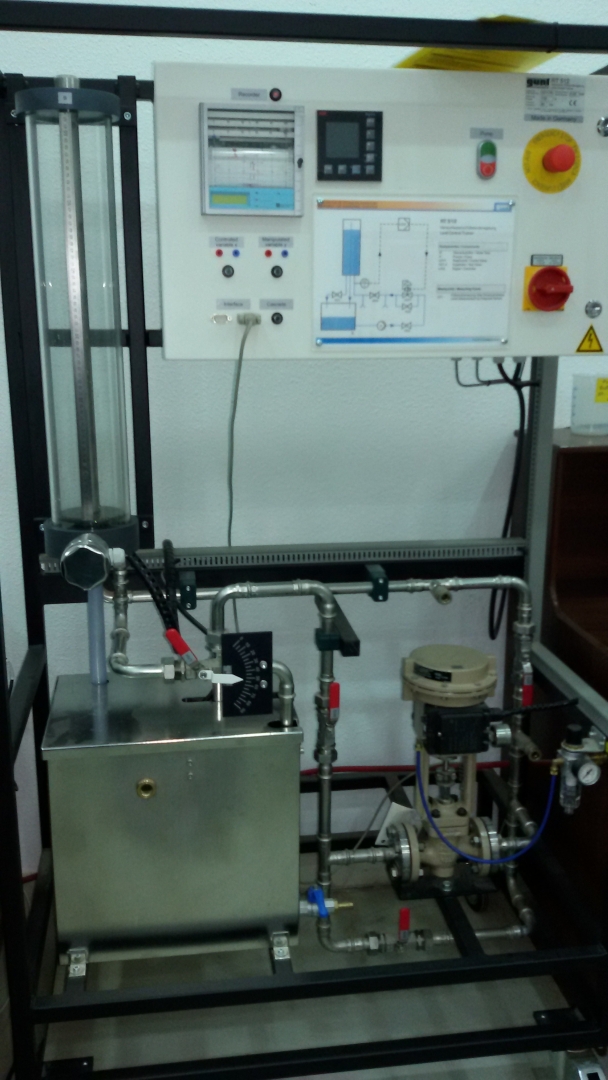

Control of Processes lab:

- Studying the characteristic of level control trainer and determination of error.

- Determination of PID controller output using performance for LCT.

- Study of flow control trainer and measurement of steady state error.

- Determination of PI controller output for FLT.

- Measurement of steady state error using Pressure control trainer configuring as single tank.

- Studying the characteristic of PCT for two vessels in series.

- Characteristic of two vessels in parallel for PCT.

- To study the characteristic of temperature control Trainer (TCT).

- Determination of PID controller output and error for TCT.

|

pH Control Trainer

|

Level Control Trainer

|

|

Flow Control Trainer

|

Temperature Control Trainer

|

Petroleum refining Engineering and Petrochemicals:

- Density testing for petroleum products.

- Color testing for petroleum products.

- Atmospheric distillation.

- Pour point testing for petroleum products.

- Cloud point testing for petroleum products.

- Pour point testing for petroleum products.

- Flash point testing for petroleum products.

- Aniline point testing for petroleum products.

|

Apparatus of density

|

|

Apparatus for measuring of pour point |

|

|