|

S.No |

Research Facilities/ Bench |

|

1 |

OPAL-RT Power Electronics & Real-Time Simulation Bench |

|

2 |

dSPACE / MicroLab Box |

|

3 |

Power System setup |

|

4 |

NHR 9410 Regenerative Power Grid Simulator |

|

5 |

CO4203-4k Lucas-Nülle Photovoltaic Setup |

|

6 |

CO4204-9T Lucas-Nülle Antenna / Communication Setup |

|

7 |

Microprocessor & Microcontroller Modules |

|

8 |

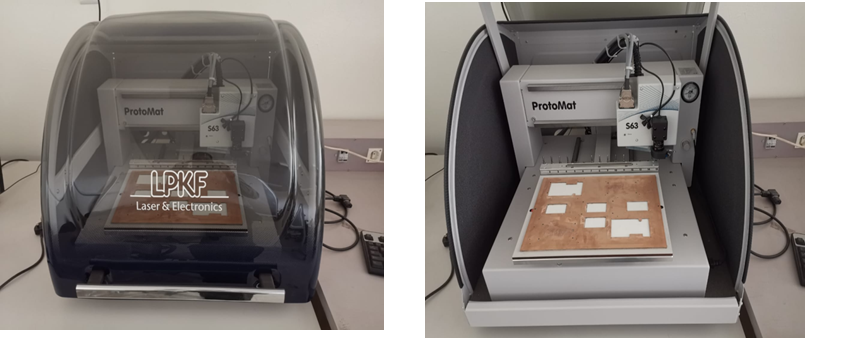

LPKF ProtoMat S63 – PCB Prototyping & Milling System |

The electrical engineering department hosts an advanced OPAL-RT Power Electronics Research Bench built around the OP4512 real-time simulator, enabling high-fidelity modelling, rapid prototyping, and Hardware-in-the-Loop (HIL) experiments for modern power systems and power electronic converters. The platform supports development and validation of control strategies for renewable integration, power quality improvement, microgrid operation, and converter-level protection using real-time execution under deterministic conditions.

The OP4512 simulator is coupled with a configurable power electronics trainer bench, enabling researchers to inject real control signals into hardware under controlled real-time simulations. This integration permits seamless transition from simulation to HIL to physical hardware implementation, significantly reducing development cycles and improving research reliability.

The OPAL-RT Power Electronics and Real-Time Simulation Bench is established to:

- Enable real-time simulation of power electronic converters, microgrids, and protection schemes using OP4512.

- Perform Controller-HIL and Power-HIL validation of converter control algorithms before deployment.

- Support advanced research in renewable energy integration, DC/AC microgrids, STATCOM, MPPT, FACTS, and fault ride-through strategies.

- Facilitate graduate and doctoral research through experimental validation of complex models in a safe, replicable environment.

- Train students and researchers in real-time digital simulation workflows used in industry and academia worldwide.

- Bridge theoretical designs with experimental implementation, reducing risk and accelerating innovation cycles.

Capabilities and Research Scope

- Real-time simulation of multi-converter systems (DC-DC, DC-AC, AC-AC)

- Closed-loop HIL testing with MATLAB/Simulink and RT-LAB

- Stability, harmonics, and protection analysis under grid disturbances

- Grid-forming and grid-following inverter research

- Microgrid energy management and fault tolerance validation

- Rapid prototyping for AI-based control and predictive control techniques

Equipment Used

- OPAL-RT OP4512 Real-Time Simulator

- Power electronics training bench with configurable converter stage

- Digital and analog I/O expansion for Controller-HIL

- MATLAB/Simulink RT-LAB integration environment

- Interface support for dSPACE 1104 and MicroLab Box systems

Electrical engineering department research lab is also equipped with advanced tools like the MicroLab Box 1202 and dSPACE 1104, providing a robust platform for cutting-edge research in control systems, real-time simulation, and hardware-in-the-loop (HIL) testing. The MicroLab Box 1202 is a versatile, all-in-one development system designed for rapid prototyping and testing of control algorithms, offering high computational power and a wide range of I/O interfaces. Complementing this, the dSPACE 1104 provides real-time processing capabilities, making it ideal for developing and testing complex control strategies. Together, these systems enable researchers and students to model, simulate, and implement sophisticated control applications, bridging the gap between theoretical research and practical implementation.

- Provide a platform for researchers and students to engage in advanced studies in electrical and electronics control systems, enabling the development, testing, and validation of complex control algorithms.

- Researchers utilize the MicroLab Box 1202 and dSPACE 1104 systems to conduct real-time simulations, helping user’s model and predict system behaviour under realistic conditions.

- Bridge the gap between theoretical models and physical implementation by allowing HIL testing, which integrates real hardware with simulated environments for more accurate and practical testing.

- This setup support rapid prototyping and algorithm development. The MicroLab Box 1202’s computational power and diverse I/O interfaces to quickly design, prototype, and test new control algorithms, accelerating the research process.

- Encourage researchers and students to apply theoretical control concepts in a practical, hands-on environment, reinforcing understanding through experimentation.

- Provide a cutting-edge research environment that supports innovation in control applications, preparing students and researchers to tackle complex, real-world challenges in engineering.

- Utilize dSPACE 1104’s real-time processing to train students in the development of control strategies that are directly applicable to dynamic, real-time systems.

The Power System setup is a state-of-the-art facility designed to provide hands-on experience in electrical power engineering. Equipped with advanced didactic benches, industrial-grade hardware, and an open SCADA software platform. This platform supports comprehensive learning and research across four major study areas: electric power generation, transmission and distribution, power utilization, and protection techniques. Students and researchers engage with real-world simulations of power systems, gaining skills in system monitoring, control, fault analysis, and optimization. Emphasizing safety and efficiency, the lab prepares students for practical challenges in power engineering, fostering both technical competencies and innovation.

The focus of the power system setup is to enable students and researchers to gain hands-on experience in electrical power engineering through interaction with advanced didactic benches, industrial-grade hardware, and SCADA software. The researchers have exposure to the response of alternator in isolated operation, synchronization issues, power system protection, Generator open circuit, short circuit test, load characteristics, three phase symmetrical short circuit, Transmission lines protection, Double Bus bar systems coupling, protection in parallel connected lines, Power system protection, Transformer protection. Over all the researchers will

- have practical experience in power system engineering.

- develop skills in power generation, transmission, distribution, and utilization.

- enhance competence in power system monitoring and control.

- enable fault analysis and optimization of power systems.

- foster technical skills in SCADA and industrial hardware usage.

- prepare for real-world challenges in power engineering.

The department is equipped with the NHR 9410 regenerative grid simulator, designed for testing grid-connected power converters, microgrid controllers, renewable energy interfaces, and grid compliance strategies under programmable AC conditions. The system provides four-quadrant operation with regeneration capability, allowing seamless injection and absorption of power back to the grid during experiments, eliminating the need for large external dissipative loads and improving energy efficiency and safety.

Objectives

The NHR 9410 bench enables researchers and students to:

- Emulate weak, distorted, and faulted grid scenarios for converter compliance testing

- Validate inverter control, anti-islanding, LVRT/FRT, droop control, and synchronization algorithms

- Conduct pre-certification testing for IEEE-1547 / IEC-61000 / UL-1741 grid codes

- Perform AC microgrid testing with programmable phase imbalance, flicker, sags, swells, and harmonics

- Support regenerative test workflows that reduce energy waste and heat dissipation

Capabilities and Research Scope

- Programmable AC grid from 0-350 V, 45-100 Hz with phase programmability

- Real-time disturbance injection (sag, swell, notch, harmonics, phase jump)

- Four-quadrant bidirectional operation with full power regeneration

- Fault-ride-through and islanding research with closed loop control

- Interface with OPAL-RT and dSPACE for HIL-synchronized testing

Equipment Used

- NHR 9410 Regenerative Grid Simulator

- Programmable AC output with harmonic shaping

- Interface I/O for controller synchronization and data logging

- Compatible with OPAL-RT OP4512 and dSPACE 1104 HIL environments

The department hosts the Lucas-Nülle CO4203-4k photovoltaic system, designed for detailed study and experimental validation of PV generation, MPPT control, grid-integration behaviour, and hybrid system interfacing. The setup provides modular PV emulation, realistic irradiance and temperature adjustment, and measurement interfaces that support both teaching and research in modern solar power engineering.

Objectives

The CO4203-4k PV setup is used to:

- Study PV module characteristics under controlled irradiance and temperature conditions

- Validate MPPT algorithms with real I-V and P-V curves

- Investigate grid-connected and stand-alone solar configurations

- Train students on PV system sizing, interconnection, safety and protection

- Support research on hybrid integration with storage, converters and microgrids

- Enable hardware-based validation of solar control strategies

Capabilities and Research Scope

- Programmable irradiance and temperature for real-world PV emulation

- Measurement of I-V and P-V curves in real time under varying conditions

- MPPT studies using incremental conductance, P&O, fuzzy/AI-based methods

- Experiments on DC-DC, DC-AC conversion and protection coordination

- Integration with OPAL-RT and dSPACE for HIL-linked PV scenarios

- Support for teaching labs, M.Sc. dissertation work and doctoral research

Equipment Used

- Lucas-Nülle CO4203-4k PV training and research bench

- Programmable sunlight/temperature emulation modules

- DC-DC & DC-AC conversion stages with instrumentation

- Measurement, logging, and supervisory software interface

The department is equipped with the Lucas-Nülle CO4204-9T antenna technology system, enabling hands-on experimentation in RF antenna theory, design, characterization, and radiation behavior. The bench supports measurements of key antenna parameters using modular radiators and sensor modules suitable for both instructional delivery and research investigations in wireless, radar, and IoT communication links.

Objectives

The antenna setup enables users to:

- Study radiation patterns, gain, directivity, bandwidth and impedance of various antenna types

- Experiment with dipole, monopole, patch, loop, and array configurations

- Validate theoretical antenna models with physical measurements

- Understand matching concepts and feeding networks for RF transmission

- Support applied research in wireless sensing, communication, and EMI diagnostics

Capabilities and Research Scope

- Built-in modules for multiple antenna geometries (rectangular patch, Yagi, log-periodic, etc.)

- Polar/radial measurement of radiation patterns with rotating sensor mount

- Impedance and VSWR characterization using matching networks

- Near-field and far-field behaviour comparison under controlled conditions

- Integration with spectrum analyzers (Spectran HF/NF) for emission and link studies

- Supports undergraduate labs, senior projects, and RF-related research

Equipment Used

- Lucas-Nülle CO4204-9T antenna training and measurement bench

- Modular antenna elements and configurable feed structures

- Rotating antenna measurement arc with detection probe

- Interface for external spectrum analyzers and logging software

The Microprocessor and Microcontroller bench provides a complete platform for embedded system development, interfacing, and real-time control research. The facility is equipped with the DL3155BRS-M24 Microcontroller Kit and the DL3155E24R 32-bit Microprocessor Module (Cortex-M3), enabling both low-level machine instruction training and high-level embedded system implementation. The DL3155BRS-M24 supports experimentation with PIC-series controllers (PIC16, PIC18, PIC24, PIC32) for digital I/O, sensor integration, A/D and D/A conversion, memory handling, motor drive control and opto-isolated interfacing. The DL3155E24R microprocessor module allows deeper exploration of 32-bit processor architecture using MASM and C, covering instruction execution, exception handling, memory structures and peripheral integration in a structured hardware environment.

Together, these systems bridge theoretical instruction with hardware-accurate execution, enabling implementation of algorithms, peripheral interfacing, communication protocols, numerical computation, and controller deployment for practical embedded applications. Students and researchers gain exposure to end-to-end embedded workflows, from assembly-level fundamentals to system-level controller design for power electronics, automation, and communication subsystems.

Equipment Included

- DL3155BRS-M24 Microcontroller Kit with PIC16/18/24/32 modular mini-boards

- DL3155E24R 32-Bit Microprocessor Module (Cortex-M3 architecture)

- MASM (Microsoft Assembler) Development Environment

- Embedded application modules (Numeric Display, Traffic Light, LCD, 7-Segment, etc.)

The department is equipped with the LPKF ProtoMat S63 PCB milling machine, enabling in-house rapid fabrication of printed circuit boards for research and instructional purposes. The system supports single-sided, double-sided, and multilayer PCB fabrication without chemical etching, allowing fast iteration from design to hardware in embedded systems, control circuits, power electronics drivers, and sensor interfaces.

Objectives

The LPKF S63 is used to:

- Prototype PCB hardware for converter control, embedded systems, IoT, and instrumentation

- Validate electronics research outputs with real fabricated controller boards

- Reduce dependency on external PCB fabrication services and turnaround delays

- Support capstone, master, and doctoral research with in-lab prototyping capability

- Enable safe, chemical-free, fast PCB production in an academic setting

Capabilities and Research Scope

- High-speed spindle milling with automated tool change

- Patterning for RF, analog, and power circuits

- Through-hole via plating support for multilayer boards

- SMD footprint accuracy suitable for fine-pitch ICs

- Workflow integration with EDA tools (Altium, KiCAD, Eagle)

Equipment Used

- LPKF ProtoMat S63 PCB Milling System

- Vacuum table and depth-control sensors

- Tool magazine for multi-step fabrication

- CAM software for automated routing and drilling

COLLEGE OF ENGINEERING

COLLEGE OF ENGINEERING